EIRICH INTENSIVE MIXERS for preparation of fibre-reinforced extruded concrete

Fibres – preferably steel, glass or plastic fibres – are added to concrete to improve its cracking and fracture behavior. To achieve the expected properties, the fibres must be distributed as evenly as possible in the concrete. This places tough demands on the mixing technology, particularly if concrete with little water and fine grain sizes are processed into small precast elements and used for concretes where the largest grain size is < 6 mm. For this reason, more and more manufacturers of precast elements made of extruded concrete are opting for mixing technology from EIRICH BIRKENMAYER

The fine-grained concrete used for small extruded components / precast elements has a stiff-plastic consistency. To ensure that the products taken from the extruder offer sufficient cohesion, plasticisers and plastic fibres are added to the concrete. This ensures the homogeneous distribution of the plasticiser and a defined separation of fibres, which are often entangled or matted, present a major challenge for concrete mixer

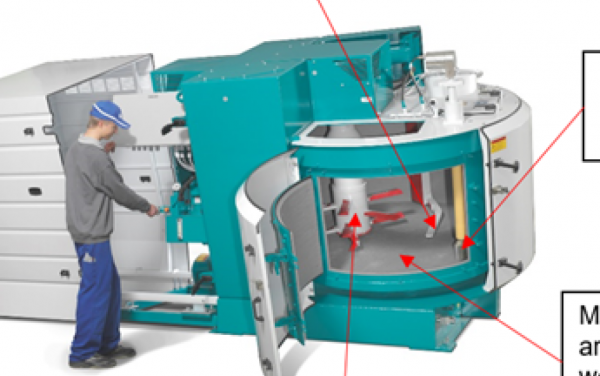

When processing fine-grained concretes of any consistency, with or without added fibres, the system design of the EIRICH INTENSIVE MIXERS offers major advantages. The mixing system (inclined rotating pan and fast rotating mixing tool) is a further development of the ring-trough and planetary mixer and was brought to the market 40 years ago

What sets this design apart for other mixing processes is the fact that the rotor can run at any speeds up to 30 m/s – and this with or against the direction of rotation of the pan. As a result, the power input into the mix can be carefully adapted to the relevant process and to its specific requirements.

Depending on the geometry and speed of the rotor,

very high specific mixing energy input (> 10 kW/100 kg) into the mixing

material is possible. With the mixing pan and rotor normally running in

opposite directions to each other, high-speed differences are generated, with

correspondingly high shear forces. As a result, the EIRICH INTENSIVE MIXER is

also ideal for preparing very stiff concrete mixes with added fibres. Furthermore,

addition of cement can be reduced by up to 10%.

The mixing principle with a rotating mixing pan, rotor and material deflector ensures complete agitation and homogeneous mix of all the material with every rotation of the mixing pan. Material transport inside the pan is separated from mixing zone which allows a very efficient use of mixing energy. With the EIRICH INTENSIVE MIXER, the dead zones are prevented because all the mixing material is fed to the mixing tool blades. This also reliably rules out segregation in the mixer.

Technical trials regularly demonstrate improved mixing results particularly in terms of preventing fiber segregation. For production plants, in addition to the mixers, EIRICH BIRKENMAYER can also supply the entire plant engineering including conveyor systems, dosing systems, weighing equipment and plant control systems. Table feeders allow material from a batch mixing process to a continuous process.

EIRICH BIRKENMAYER can look back on many decades of experience in many applications, including the production of concrete roofing tiles or spacers. The EIRICH BIRKENMAYER brick and block machines have also benefit from the EIRICH INTENSIVE MIXER design to reduce the amount of cement used in a given mix design. All this experience will benefit new and old customers to produce high quality concrete for every application.

Birkenmayer South Africa is part of the Eirich Group, a company that operates in 14 countries on 6 continents across the globe. Birkenmayer is backed by world class manufacture within the world of concrete mixers and brick and block plants

More information Herbert

Cullum, Tel: +27(0)11 970 3880 / Cell: +27(0)82 417 6893

e-mail: sales@birkenmayer.co.za / www.birkenmayer.co.za / www.eirich.com